| 2005 |

|

YEAR BOOK |

Trinity College Dublin

|

Research in Mechanical & Manufacturing Engineering at TCD

|

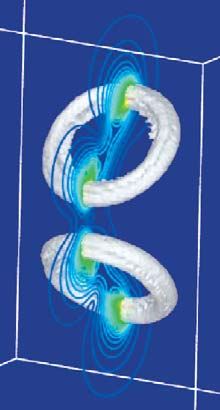

The Fluids & Vibrations Group continues to work on a wide range of interdependent disciplines with engineering applications. The areas in which the work is focused are Fluid Mechanics, Aeroacoustics, Vibrations & Acoustics, Thermodynamics & Combustion and Heat Transfer. The expertise ranges from the development of advanced measurement and analysis techniques to analytical and numerical modelling including the development of new technologies for aircraft noise reduction and modelling heat transfer in complex systems. State of the art equipment includes laser Doppler anemometry (LDA), particle image velocimetry (PIV) and other high speed imaging systems for flow visualisation. This is supported by the development of efficient methods for computational fluid dynamics (CFD) for analysis of jet flows and flow structure interactions.

Activities in Manufacturing & Materials include Finite Element Analysis of Machining & Forming Processes, Analysis of Wear and Lubrication, Mechanics of Grinding and Fracture Mechanics including Fatigue. Recent work includes participation in the Microman project which is developing methodologies for use in Irish Manufacturing at the microlevel.

Contact: Professor John Fitzpatrick, Department of Mechanical and Manufacturing,

Trinity Colege, Dublin 2;

Web: www.mme.tcd.ie.