| 2004 |

|

YEAR BOOK |

Dublin City University

|

Magnesium alloys for low weight vehicle structures

|

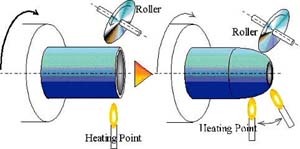

In order to fully take advantage of the weight savings promised by the use of magnesium alloys for vehicle structures, it is important that advanced manufacturing methods are used to manufacture the structure. Traditionally magnesium alloys have been used in castings, and these castings have been further machined to produce complex parts. Near-net-shape manufacturing processes have the potential to provide even lighter vehicle structures when used with magnesium alloys. Near-net-shape processes, such as hydroforming and spin-forming, are cheaper and less complex than the alternative, which is to machine the component from a casting or to weld a number of parts together. A significant advantage of these processes over casting technology is that they produce a seamless component.

Researchers at the School of Mechanical and Manufacturing Engineering at DCU, together with research partners from the Tokyo Metropolitan University in Japan, have been developing processes to manufacture vehicle components from magnesium alloys. Processing of magnesium alloys is highly complex as, in order to successfully form a magnesium alloy, a temperature of at least 250 degrees is required. This results in the requirement of a complex local heating and cooling system to be used during the forming process. The emphasis of the research is to use advanced computational modelling tools, together with intelligent optimisation techniques to optimise the manufacturing process before carrying out experiments. To date this has resulted in the development of an optimised spin forming process to produce pressure vessels for a vehicle fuel system, an optimised deep drawing process, and an optimised hydroforming process. These processes are now being used to manufacture vehicle components by industrial partners in Japan.

Contact: Dr Bryan Mac Donald, School of Mechanical and Manufacturing Engineering, Dublin City University, Glasnevin, Dublin 9;

Tel: +353-1-700 8046; Fax: +353-1-700 5345; E-mail: [email protected]