| 2004 |

|

YEAR BOOK |

Waterford Institute of Technology

|

From simulations of vehicle networks, to virtual reality

|

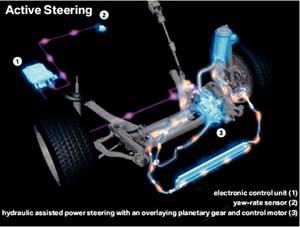

This is the modern automotive industry

Engineers at Bosch, in conjunction with engineers from Mercedes-Benz, as well as Intel, developed one such system called CAN (Controller Area Network), allowing a network of electronic components to be installed into passenger cars, each component controlled using software to allow it to send and receive messages along the network.

Testing in the Real world

Testing of electronic components began with the design of the prototype, then testing out the result on the actual hardware. This was cumbersome to deal with and hard to track and follow changes and faults. Any fault discovered needed to be re-coded and re-deployed onto a chip for further testing. This prototyping methodology is coming of age with the use of simulation software.

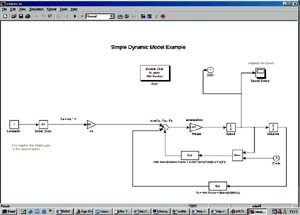

Simulation software

Advances in simulation software, such as MATLAB's SIMULINK, allow for the simulation of dynamic and real-time systems. Such software uses sets of blocks, each performing a mathematical task, that can be linked together in a diagram form, each block acting on the input from the previous block and calculating an output for the next block in line. As in the illustration, electronic systems can be modelled showing the flow of information from the source to the output, and the calculations in between in a graphical format. Blocks can be designed in order to mimic their real world counterparts and, when all is completed, in the virtual world it is possible to link the simulation to a real world interface. Diagrams are then joined together to form a virtual look at a whole system.

From simulation to virtual reality

The increasing usage of software in cars, as well as simulation of all areas of design and testing, in conjunction with increased computing power, has allowed for a decrease in cost, design-time, fault-maintenance, and an increase in the ease of data retrieval, and complexity of designs. 'Virtual simulation' according to BMW's research and development centre, is indispensable today in the automotive industry. According to General Motors 'expanded use of virtual reality will allow a global exchange of design proposals', through teams in different countries working together in real-time. Creating software simulations in a virtual world vastly improves all the above-mentioned areas: it has reduced development times for a new car model from six years down to just 21/2 years, and is beginning to lead us into an exciting era of car design.

Centre for Automotive Research

The Centre for Automotive Research, established in 2000 in Waterford Institute of Technology, is a growing research centre. It has a number of postgraduate researchers, of which some are largely dealing with the use of simulation software in order to design new techniques in various aspects of car design and technology. The use of simulation software and the knowledge gained from it is seen as a great advantage in the automotive industry in its transition to increased software usage.

Contact: Web: www.wit.ie/car