| 2004 |

|

YEAR BOOK |

Cork Institute of Technology

|

Do surgical solutions influence the performance of bone cement?

|

|

|

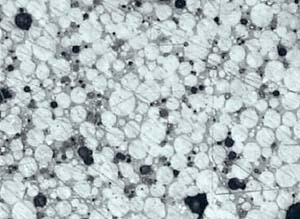

Polymethylmethacrylate (PMMA) bone cement is a polymer used to anchor the prosthesis during joint replacement surgery. The polymer powder is mixed with the liquid monomer and inserted into the bone cavity in a doughy state immediately prior to insertion of the prosthetic components.

Since the inception of joint arthroplasty, hydrogen peroxide (H 2 O 2 ) has been widely used as a haemostatic agent to reduce the lamination of blood products in the bone cement as it is being introduced to the cancellous bone bed. However, orthopaedic surgeons based in Cork have voiced concerns that the hydrogen peroxide remaining in the bone bed may alter the material properties and performance of the PMMA. This, in turn, may weaken the initial fixation and lead to loosening of the implant.

Over one million prosthetic joints are implanted annually worldwide, and approximately 80% of all subsequent failures leading to revision surgery are caused by aseptic loosening. It is of critical importance, therefore, to determine and analyse any factors which may weaken the initial fixation of the prosthesis and consequently lead to potentially numerous failed prosthetic joints.

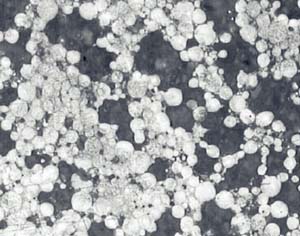

Starting with uncontaminated PMMA bone cement, a series of tests have been performed at the Biomedical Engineering Research facility at CIT. These included measurement of the doughing time, maximum temperature and setting time, compressive strength, bending modulus and bending strength, tensile modulus and strength, hardness, fatigue strength, and microscopic examination of laboratory prepared samples of bone cement. The same tests are currently being repeated on bone cement samples contaminated with H 2 O 2 of 3%, 6% and 10% concentrations, and results to date are indicating a significant reduction in structural properties of the PMMA for all concentrations of H 2 O 2 .

During the surgical procedure, only a relatively thin outer layer of cement comes in contact with the H 2 O 2 , while the samples tested were uniformly contaminated through the bulk material. Therefore, further work will be carried out to investigate notch sensitivity and crack growth in the cement mantle with a thin contaminated layer, and modelling of a joint (e.g. the acetabular component of the hip arthroplasty) both with and without a thin outer layer of the PMMA mantle contaminated with H 2 O 2 . The impact of the hydrogen peroxide contamination on the long term stability of the joint fixation can then be predicted.

Contact: Dr Keith Bryan, Mechanical & Manufacturing Engineering Department, Cork Institute of Technology, Bishopstown, Cork; E-mail: [email protected]