| 2004 |

|

YEAR BOOK |

Teagasc � Dairy Products Research Centre, Moorepark, Fermoy, Co. Cork

|

Better cheesemaking efficiency

|

In the pilot scale cheesemaking studies, all cheeses were made under highly standardized conditions. Increasing pasteurization temperature from 72 to 78.5 �C, at holding times of 26-40 seconds, resulted in higher levels of whey protein denaturation and higher moisture (~ 4%) in the cheese but reduced fat recovery from ~89 to 83% of total milk fat to cheese. Regression analysis of data indicated that the weight of cheese per 100 kg of milk with fixed levels of casein and fat increased significantly with pasteurization temperature. However, on normalizing the moisture content of the different cheeses to 38%, the weight of moisture-adjusted cheese per 100 kg of milk with fixed levels of casein and fat decreased significantly with pasteurization temperature. The use of higher pasteurization temperature would appear particularly amenable to exploitation as a means of producing high-moisture, short-ripened, mild-flavoured Cheddar or Cheddar-like curd.

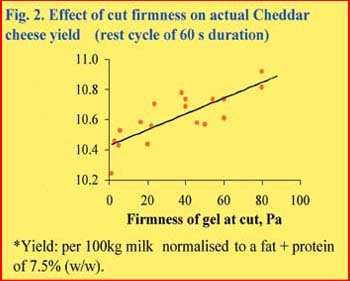

Owing to seasonal variations in milk composition, and the commercial practice of cutting the gel on time rather than firmness, research in the Dairy Products Research Centre found that firmness of gel at cutting at commercial level can vary by as much +/� 30 %. Set against this background, the project evaluated the effect of varying firmness at cut in the range 1 to 80 Pa (Figure 1) on the composition and yield of Cheddar cheese. Pa is a unit of stress and in this context it is the unit of elastic shear modulus which is an index of curd firmness as measured using low strain, amplitude oscillation rheometry. Our results clearly showed that milk gels could be cut at a range of firmness values, ranging from ~0.5 to 80 Pa, while giving satisfactory cheese manufacture. Increasing the firmness at cutting from 0.5 to 80 Pa resulted in:

-

higher cheese moisture and moisture-in-non fat substances,

-

lower levels of fat and protein in cheese,

-

lower cheese pH,

-

a trend towards higher fat losses in cheese whey on cutting at firmness values > 40 Pa,

-

higher levels of curd fines in cheese whey, again suggesting a lower fracture strain and greater brittleness of the stronger gels,

-

higher actual cheese yield

(Figure 2),

undoubtedly a consequence of the increased moisture content.

The effects of different rennets were evaluated for their effects on Cheddar cheesemaking efficiency and quality: standard calf rennet (SCR), fermentation produced chymosin (FPC), Rhizomucor pusillus proteinase (RPP), Rhizor miehei proteinase (RMP), and Cryphonectria parasitica proteinase (CPP). Rennet type did not significantly affect cheese composition, actual cheese yield or moisture-adjusted cheese yield; however, the RPP rennet gave the lowest mean cheese yield and moisture content. Rennet type significantly affected the level of protein degradation and the rheological properties of the cheese. The use of RPP and CPP rennets led to higher levels of primary proteolysis, (i.e. a measure of the degree of enzymatic degradation of the caseins in cheese), a lower fracture strain, and cheeses that were shorter and more crumbly than those made using SCR or FPC.

The survey of the Irish Cheddar cheese plants indicated significant variations in cheesemaking efficiency. The survey identified critical points in cheese manufacture and whey processing where practices have a large impact on efficiency. Data generated by the survey (e.g. levels of whey protein denaturation, fat recovery, levels of moisture and cheese-solids-non-fat-non-protein) has been used in compiling coefficients for cheese yield prediction formulae. The prediction formulae form the basis of the 'Percentage Cheesemaking Efficiency' concept, which expresses the actual yield of a target cheese type/recipe as a percentage of that expected, based on the composition of the milk. This concept has several practical benefits as it provides an index of cheese plant efficiency, indicates efficiency variations across a cheesemaking season or between factories, assists efficient planning of capital expenditure and cheese production, and facilitates decisions on product mix across sites.

Contact: Dr Tim Guinee, Tel: 025 42204;

E-mail: [email protected]