| 2004 |

|

YEAR BOOK |

Teagasc – The National Food Centre, Ashtown, Dublin 15

|

Ireland – the Food Island

|

Small and Medium Sized Enterprises and Innovation

In Ireland, 72 percent of all food enterprises are classed as 'small', having less than 50 employees, while 26 percent are classed as 'micro enterprises', having less than 10. In total, these enterprises provide employment for approximately 8,600 people and are extremely important to the Irish economy, creating employment in many rural areas and playing a key role in positioning Ireland as the 'Food Island' internationally. Innovation is crucial to the survival and growth of these enterprises and to their competitive position. Previous research, however, indicates that small and very small food processing enterprises are less innovative compared to other sectors of the manufacturing industry. To address this problem, research, funded by the European Union, was undertaken by a consortium of universities and research institutes. Seven countries across Europe, including Ireland, were involved in the study. The research aimed to ascertain the factors affecting innovation in small food firms, and determine their relative importance.

A standardised survey, designed to measure and explain the innovative performance of small food firms and their relationship to rural development, was conducted in each country. In Ireland, top managers from 60 small food processing enterprises were interviewed. The interviews were conducted in two regions, the Border region and the Southwest.

The study highlighted the extent of innovation in small food firms. Eighty five percent of the firms in the sample had innovated to some extent over the five-year period preceding the study. Similar figures were achieved in the other European regions examined. A number of internal factors were found to have an impact on innovation. Among the more interesting findings were the correlations between innovation and younger firms and younger managers. The predicted relationship between innovation and investment in R&D, investment in training, and the percentage of technically qualified staff, was confirmed. In relation to the impact of external factors on innovation, the study found that interaction with equipment suppliers, customers, similar enterprises, and external research agencies had a positive impact on innovation. Government assistance was also positively related to innovation.

The findings will provide guidelines to policy makers about the determinants of innovation and growth in this sector. Based on these guidelines, policies will be drawn up to support and facilitate further development. This will have a positive impact on the aggregate performance of small food firms and, by implication, the economy of rural regions.

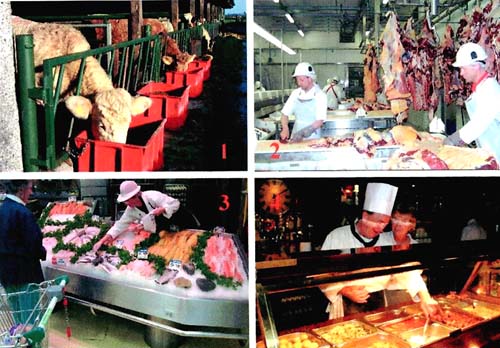

Food Safety Management Systems from Farm to Fork

There are an estimated 45.4 million cases of food poisoning within the EU every year, which represents an unacceptable social (human suffering) and economic (health care and lost working days) cost. Risk analysis is a new, proactive, preventative approach to food safety, and is becoming the new cornerstone in producing safe, acceptable food. The European Union – Risk Analysis Information Network (EU–RAIN) is an EU-funded project aimed at developing food safety management systems for farm production, meat processing, retailing, catering, and domestic kitchens. EU-RAIN involves research institutes and consumer organisations from 13 European countries and Canada, and is led by Declan Bolton and Bláithín Maunsell of The National Food Centre.

The objectives of EU-RAIN are: (1) to establish an EU food safety risk assessment information network and web-based database; (2) to focus on catering as the current weak link in risk assessment data and to identify risk assessment research priorities for the future; (3) to develop Hazard Analysis and Critical Control Point (HACCP) based risk management strategies through the development of harmonised farm, meat, retail and catering HACCP procedures/systems; (4) to review epidemiological methodologies and data in relation to food poisoning, with particular focus on its application in risk assessment; and (5) to develop risk communication strategies for consumers, scientists and regulators based on the psychological and marketing sciences.

The work plan involves a series of conferences/meetings held over the three-year duration (2003–2006) of the project. Highlights to date have been the inaugural EU-RAIN meeting 'Project Framework and Database' (Ireland, July 2003), and two major international conferences, 'Catering Food Safety: A Responsibility Ignored?' (Hungary, November 2003), and 'Farm to Fork Food Safety: A Call for Common Sense' (Greece, May 2004). Forthcoming conferences are as follows: Epidemiology (Italy, December 2004), The Psychology of Food Safety (Sweden, May 2005), and Project Review (Ireland, November 2005). EU-RAIN conferences are advertised, inviting anybody with an interest in the selected topics to attend.

EU-RAIN brings food safety experts together, enabling them to discuss issues and share ideas with the common goal of safer food for everybody. The deliverables include: a risk assessment database; data for microbial risk assessment (from farm to fork); HACCP based risk management guidance documents for farm HACCP; beef, pork and lamb slaughter and processing HACCP; retail and catering HACCP; a HACCP based guide for domestic kitchens; a food safety risk communication strategy. Further information and access to the risk assessment database is available from the EU-RAIN website (www.eu-rain.com).

Optimising the quality of gluten-free breads

Coeliac disease is a life-long intolerance to the gliadin fraction of wheat and the prolamins of rye (secalins), barley (hordeins) and oats (avidins). The reaction to gluten ingestion by sufferers of coeliac disease is inflammation of the small intestine, leading to the malabsorption of several important nutrients. Coeliac disease is more common in Ireland than anywhere else in the world. It is particularly prevalent in the West of Ireland. Conservative estimates in Ireland consider that approximately ten thousand people, who regularly feel unwell without ever knowing why, suffer from undiagnosed coeliac disease. The worldwide incidence of sufferers of coeliac disease has been predicted to increase by a factor of ten over the next few years, resulting in a growing market for gluten-free products. Gluten is the main structure-forming protein in flour and is responsible for the elastic characteristics of dough, contributing to the appearance and crumb structure of many baked products. The replacement of gluten, particularly in a bread formulation, presents a major technical challenge, as it is an essential structure-building protein, that is necessary for formulating high quality breads.

Response Surface Methodology (RSM) is a statistical tool that can be applied in the development and optimisation of cereal-based products. It allows optimum ingredient levels to be determined while, at the same time, minimizing the number of baking trials without losing any information related to all possible experimental combinations. RSM quantifies the main effects of the ingredients and describes the interactions between them. The current study was carried out by Eimear Gallagher, Denise McCarthy and Ronan Gormley at The National Food Centre. RSM was used to optimise a gluten-free bread formulation based on rice flour, potato starch, skim milk powder, hydroxypropylmethylcellulose (HPMC) and water. HPMC and water were the critical ingredients in this study.

Acknowledgements

These projects were funded by the EU Framework Research Programme and the Department of Agriculture and Food's Food Institutional Research Measure (FIRM) Programme.

Contacts: Dr Bláithín Maunsell, Dr Declan Bolton,

Ms Denise Mahon, Dr Ronan Gormley, Ms Eimear Gallagher, Ms Ciara Mc Donagh,

The National Food Centre, Ashtown, Dublin 15; Tel: 01–8059500; Fax: 01–8059550;

E-mail: [email protected] , [email protected] , [email protected] , [email protected] , [email protected] , [email protected] , [email protected]