Athlone Institute of Technology's longstanding tradition and expertise in the complementary niche

areas of polymer science/engineering and toxicology led to the establishment of the Centre for

Biopolymer & Biomolecular Research (CBBR) in 2000. The CBBR has recently relocated to a new

suite of laboratories in the Midlands Innovation & Research Centre (MIRC) on the East Campus.

Athlone Institute of Technology's longstanding tradition and expertise in the complementary niche

areas of polymer science/engineering and toxicology led to the establishment of the Centre for

Biopolymer & Biomolecular Research (CBBR) in 2000. The CBBR has recently relocated to a new

suite of laboratories in the Midlands Innovation & Research Centre (MIRC) on the East Campus.

Underpinning the research activities of the centre is state of the art equipment that support

biomaterial synthesis, thermal analysis (modulated differential scanning calorimeter, ;<-thermal

analyser, dynamic mechanical thermal analyser), impedance spectrometry and rheometry. All in

addition to gene expression microarray technology, real-time quantitative PCR, automated DNA

fragment analysis, multilabel plate analysers, protein purification and Comet assay image analysis

capabilities. Significantly, the procurement of such equipment has been facilitated by AIT's success

in attracting > � 6m in research funding in life science/polymer over the past number of years.

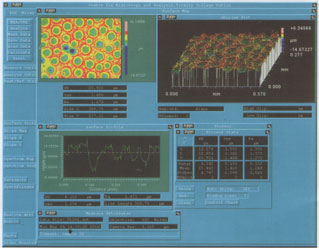

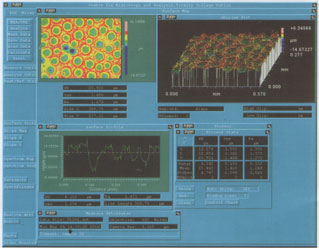

Figure 1 A white light profilometry scan for a Thermoplastic Elastomer-g-Hydrogel illustrating 2D

and 3D surface profiles as well as the PV value, 15.44 �m and the RMS parameter, 1.468�m

Biopolymer research at CBBR has focused on the synthesis and characterisation of biomaterials for

a variety of medical/healthcare applications. Biomaterials have been synthesised for use in tissue

engineering, drug delivery, coatings and wound care technology among others. Amajorfocus is the

development of 'smart' polymeric materials: materials that can change their structure and function

in response to an external stimulus, such as pH, temperature, ionic strength, electrical stimulus

etc. One major class of biomaterial that has been studied extensively at AIT is the hydrogel. They

have been widely used in applications such as controlled drug release because of their

biocompatibility with the human body and also because they resemble natural living tissue more than

any other class of synthetic biomaterial.

Figure 1 A white light profilometry scan for a Thermoplastic Elastomer-g-Hydrogel illustrating 2D

and 3D surface profiles as well as the PV value, 15.44 �m and the RMS parameter, 1.468�m

Biopolymer research at CBBR has focused on the synthesis and characterisation of biomaterials for

a variety of medical/healthcare applications. Biomaterials have been synthesised for use in tissue

engineering, drug delivery, coatings and wound care technology among others. Amajorfocus is the

development of 'smart' polymeric materials: materials that can change their structure and function

in response to an external stimulus, such as pH, temperature, ionic strength, electrical stimulus

etc. One major class of biomaterial that has been studied extensively at AIT is the hydrogel. They

have been widely used in applications such as controlled drug release because of their

biocompatibility with the human body and also because they resemble natural living tissue more than

any other class of synthetic biomaterial.

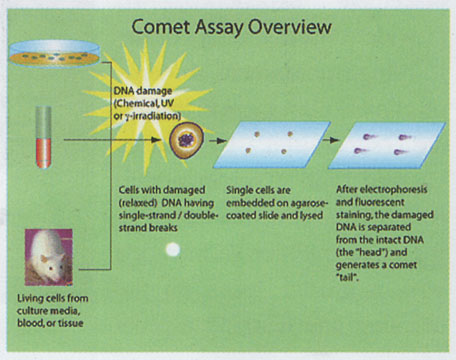

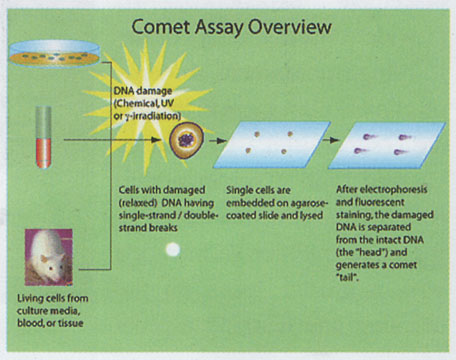

Figure 2. Basic single cell gel electrophoresis (SCGE) Comet assay schematic

Biomolecular research at CBBR to date has focussed on the development of high throughput

screening assays for the detection of DNA damage and mutation induction based upon such techniques

as the Comet assay, automated fragment analysis and real-time PCR. DNA microarray technology has

also been employed in the detection of gene expression changes following cellular exposure to

various polymeric materials. Moreover, a battery of cell and molecular screening assays including

reporter- gene systems are currently under development with partner laboratories for the detection

and characterisation of endocrine disrupters, which of course include a range of chemicals used in

the plastics industry such as phthalates and bisphenol-A. From a tissue engineering perspective

cytoskeletal proteins produced via a novel cell-free expression system are currently under

investigation for use as scaffolds, while traditional colorimetric-based viability assays and

regulatory-approved genotoxicity tests are used on a routine basis to evaluate the biocompatibility

of various polymeric materials. The CBBR has developed working tissue models of skin, liver and

vascular systems for toxicological analysis.

Figure 2. Basic single cell gel electrophoresis (SCGE) Comet assay schematic

Biomolecular research at CBBR to date has focussed on the development of high throughput

screening assays for the detection of DNA damage and mutation induction based upon such techniques

as the Comet assay, automated fragment analysis and real-time PCR. DNA microarray technology has

also been employed in the detection of gene expression changes following cellular exposure to

various polymeric materials. Moreover, a battery of cell and molecular screening assays including

reporter- gene systems are currently under development with partner laboratories for the detection

and characterisation of endocrine disrupters, which of course include a range of chemicals used in

the plastics industry such as phthalates and bisphenol-A. From a tissue engineering perspective

cytoskeletal proteins produced via a novel cell-free expression system are currently under

investigation for use as scaffolds, while traditional colorimetric-based viability assays and

regulatory-approved genotoxicity tests are used on a routine basis to evaluate the biocompatibility

of various polymeric materials. The CBBR has developed working tissue models of skin, liver and

vascular systems for toxicological analysis.

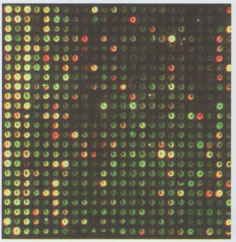

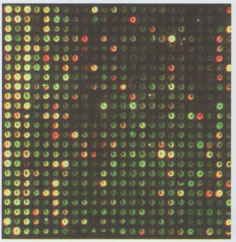

Figure 3. A typical DNA microarray scan illustrating Cy3 and Cy5-labelled control and treated

cDNA hybridising to a custom made oligonucleotide microarray.

Going forward a major focus of CBBR will be the development of robust, high throughput methods

for nanotoxicology, increased application of toxicogenomics based upon microarray and real-time PCR

technologies, enhancement of medical device coatings and drug delivery strategies and the continued

development of more appropriate systems and methodologies for toxicity assessment.

Figure 3. A typical DNA microarray scan illustrating Cy3 and Cy5-labelled control and treated

cDNA hybridising to a custom made oligonucleotide microarray.

Going forward a major focus of CBBR will be the development of robust, high throughput methods

for nanotoxicology, increased application of toxicogenomics based upon microarray and real-time PCR

technologies, enhancement of medical device coatings and drug delivery strategies and the continued

development of more appropriate systems and methodologies for toxicity assessment.

Contact: Dr Paul Tomkins

Athlone Institute of Technology,

Athlone, Ireland

Tel 09064

24453

E-mail:

[email protected]

Dr Sinead Devery. E-mail:

[email protected]

Dr Clem Higginbotham E-mail:

[email protected]

|