| 2003 |

|

YEAR BOOK |

Institute of Technology Tallaght

|

Finite Element Analysis and Modal Analysis of engineering products during dynamic impact loading

|

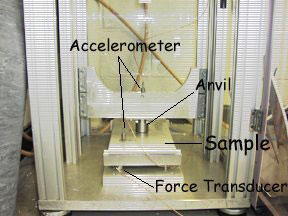

Our research evaluates an impact by modelling the whole event, the motion, the contact and the non-linear behaviour of the material. Modal analysis is being used to predict the permanent deformation of components when subjected to impact loads. The first stage of the investigation involves the modal testing of standard components - in this case aluminium plates - resulting in the extraction of the natural frequencies and mode shapes of the samples tested. From this, a mathematical summation is performed to extract the operating deflection shapes at specified frequencies. When the operating deflections for specified frequencies are known, it is then possible to input a zero frequency and mathematically extract a permanent deflection due to a known static input force at a known location.

Impact testing is conducted to obtain specimen deformations. Finite element analysis (FEA) is also used to predict the natural frequencies and mode shapes of the components. The impact loads are modelled using ANSYS with an explicit solver (Ls-Dyna). The material properties for these models are obtained from a stress strain test. Data extracted from testing and FEA models include displacement, acceleration, velocity, and reaction forces. Test, FEA and a mathematical model are finally compared and a conclusion made.

Contact: Kenneth Hughes, Department of Mechanical Engineering, IT Tallaght, Old Blessington Road, Tallaght, Dublin 24:

E-mail: [email protected]