| 2003 |

|

YEAR BOOK |

The National Food Centre

|

What Drives Food Research ?

|

Figure 1: Antisense RNA technology is being assessed as a method of killing specific food poisoning bacteria (adapted from www.hybridon.com ).

In recent decades, a fundamental shift occurred in the factors that determine industrial competitiveness. Traditionally, competitiveness relied heavily on the price factor, nowadays trading on price alone will not ensure success. Other important competitive factors are food safety, healthy eating and convenience, as well as consistency of quality.

Issues of food ethics such as animal welfare, fair trade and the environment, are increasingly important in winning consumers. Indeed, one leading food retailer in Europe differentiates between 'standard' food products which compete on conventional issues such as food safety and quality, and 'select' products which have ethical and societal characteristics; beef, pork and chicken products fall into the latter category.

Such is the intensity of competition in the food business, that each new competitive factor gradually becomes a utility, that is, necessary but not sufficient for success. Ultimately, competitiveness comes down to understanding what consumers need, even before they know it themselves, and translating it into successful products. Without this knowledge and guidance, new product development is a hit or miss affair. Market studies are essential to guide new product development activities and technical research.

Research for Irish food companies

A sample of four of the 57 research projects in progress in 2003 at The National Food Centre are featured in this article.

Molecular technologies and food safety

Illness due to microbiological contamination of foods is of major concern to consumers, retailers and manufacturers alike. Traditional plating methods for the detection of pathogenic bacteria from foods are time consuming. This has led to the development of molecular techniques for the rapid, quantitative and specific detection of pathogens contaminating food. Robert Downer and colleagues are developing molecular techniques for the detection and elimination of pathogenic bacteria from food and water.

Polymerase chain reaction (PCR) is a method of detecting and amplifying specific DNA sequences. At The National Food Centre this technique has been applied to the detection of food-borne pathogens by the amplification of genes that are synonymous with a particular organism. The use of Real-Time PCR, which uses fluorescence to detect the products of the PCR reaction in real time, and immunomagnetic separation (IMS), have greatly increased the specificity and speed of this approach.

Pulse field gel electrophoresis (PFGE) and random amplified polymorphic DNA (RAPD) techniques are being used to detect and differentiate bacterial species responsible for food poisoning in Ireland, such as verocytotoxic E. coli (VTEC) and Campylobacter species. This information is being used to establish a reference database at The National Food Centre that will facilitate studies on the incidence and prevalence of these organisms in Irish foods.

Antisense RNA technology, which uses single stranded nucleic acids to target the messenger RNA of essential genes and inhibit protein expression, is being examined as a method of killing E. coli o157:H7 and other VTEC serogroups. Methods to improve the uptake and efficacy of antisense molecules are also under development. The establishment of such rapid and efficient methods for the detection and elimination of food-borne pathogens will benefit all parties involved in the management of food safety.

Mild processing of broccoli by sous vide

In sous vide cooking, raw or par-cooked food is sealed in a vacuumised laminated plastic pouch, cooked under controlled mild conditions, rapidly cooled, and stored chilled or frozen. The pouch is then reheated before serving. The process gives high quality products due to the mild heating, the absence of oxygen, and the fact that flavours and other constituents are sealed in. The shelf-life of sous vide products is 20-30 days at 4�C but much longer at deep freeze (-30�C). The chilled regime is less safe due to the ease of temperature abuse and the potential for Clostridium botulinum growth. The frozen regime is safer but may damage some aspects of product quality, especially texture.

Fergal Tansey, Tanja Budde and Ronan Gormley are researching the sous vide cooking of consumer size portions (150-250 g) of fish, meat, pasta, potatoes and vegetables, including broccoli. Pre-treatment of broccoli florets in water at 50�C for 15 mins gave a firming of texture (due to the action of pectin-methylesterase), which was maintained during sous vide treatment and follow-on freezing or chilling. Increasing cook times softened broccoli texture as did freezing in comparison with chilling. It is important, therefore, to optimise pre-treatment, cook time and freezing conditions in order to obtain a good texture in the final product. Sous vide cooking had a conserving effect on vitamin C in broccoli (due to the absence of oxygen in the packs) compared with conventional cooking. These tests indicate that sous vide / freezing is a suitable processing technology for broccoli portions in consumer size packs.

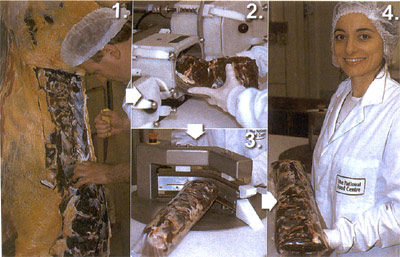

The 'TenderBound' system of beef packing

A novel beef packing system is being developed by Declan Troy and Aileen O'Sullivan, with potential benefits to industry of increased meat yield, reduced energy costs resulting from less chiller space and a saving of refrigeration input, quicker throughput of meat in the packing plant, and a reduction in labour and transport costs.

In the new system, the carcass is 'hot-boned', that is, the meat is removed shortly after slaughter rather than after chilling in the conventional manner. The hot meat is tightly packaged in elasticated film using a 'PI-VAC' machine.

The new system overcomes two disadvantages which have held up the adoption of hot-boning by industry: the toughening which is caused by muscle contraction during chilling of hot-boned meat, and the distortion of the shape of the hot-cut meat. PI-VAC operates by widening a tube of elastic film into which the hot meat is inserted and releasing the stretched film so that it tightly binds the meat cuts. The restraining force of the film prevents muscle contraction and toughening.

'Hot-boned' meat packed in PI-VAC can be chilled quickly, to give beef of consistently tender eating quality. In contrast, cuts that were similarly chilled without PI-VAC restraint were much more resistant to shear force, even after 14 days of maturation.

The sarcomere length reveals the molecular structure of muscle and was considerably increased in meat subject to restraint by the PI-VAC (1.7 microns) compared to beef that was hot-packed without restraint (1.3 microns).

Using the new system, beef cuts can be segregated before chilling, allowing individual cuts to receive the optimum maturation for their intended culinary use.

The new system has the potential to revolutionise beef processing in a way not seen since the introduction of vacuum-packaging three decades ago.

Market access for small-scale food manufacturers

Ireland's several hundred small-scale food manufacturers are facing increasing problems for market access and competitiveness. The National Food Centre is looking at new ways of managing the supply chain from manufacturer to customer, in partnership with research institutes in six European countries.

Maeve Henchion and colleagues examined the different types of supply chains used by Irish food manufacturers. They found most use a variety of supply chains, (see figure 4). However, there is increasing pressure on manufacturers to use intermediaries (e.g. distributors), due to retailers' and caterers' need to reduce costs. While the use of intermediaries means that manufacturers would not have to worry about how products are transported, there are some concerns that they will have less control over where and how their products are sold. A solution for the manufacturer may be to work directly with retailers/caterers on marketing issues, for example promotions, and use the intermediary only for logistics.

Communication and information technology (C&IT) will be increasingly important to all members of the supply chain. It can (1) create barriers to entry, manufacturers without certain C&IT capabilities will not be allowed to supply particular markets, (2) create new ways of reaching consumers, for example through internet sales, and (3) help members of the chain to communicate more effectively.

New product development (NPD) is important in maintaining market access because retailers/caterers always want something new. While some food manufacturers are very good at coming up with ideas, many do not have the time or money to convert these ideas into products.

The research will now look at how the State and support agencies can help small-scale food manufacturers to overcome problems of market access, competitiveness and NPD.

Acknowledgements

The research featured in this article is part-funded by the EU Framework Research Programme, also the Department of Agriculture and Food's FIRM Programme, and Enterprise Ireland's Advanced Technologies Research Programme.

Contacts: Dr Robert Downer, Dr Ronan Gormley, Mr Fergal Tansey, Mr Declan Troy, Dr Aileen O'Sullivan, Dr Maeve Henchion,

The National Food Centre, Ashtown, Dublin 15; Tel: 01-8059500; Fax: 01-8059550;

E-mail: [email protected] ;

[email protected] ;

[email protected] ;

[email protected] ;

[email protected] ;

[email protected]