| 2003 |

|

YEAR BOOK |

University of Ulster

|

The Engineering Composites Research Centre (ECRE)

|

In recent years, composite materials have gained importance in many areas of application. There are two main reasons:

|

� their high specific properties (e.g. strength, stiffness) in comparison to

metals

� the ease with which complex three dimensional shapes can be made. |

Due to its low cost, glass fibre was the first recognised reinforcement, but carbon and aramid fibres have found greater acceptance, particularly in the aerospace industry. While these new reinforcements are very expensive, their significantly improved performance makes them cost effective. Alternative routes of manufacture include autoclaving for high performance applications, while resin transfer moulding or resin film infusion offer attractive alternatives if higher production rates are required.

Composite materials are very often considered to contain fibres, but in their broadest context, they can be considered to include blends or alloys of polymers, rubbers and additives. These materials can be tailored for specific applications where properties can be engineered into the products.

Developments in textile technology, particularly through technical textiles, have led to the design and manufacture of multi-layered complex reinforcements of near-net shape for complex components to be used in place of the labour-intensive hand-lay up route for manufacture. This permits a much more efficient use of materials with consequent cost reductions - although interaction of the constituents may adversely affect performance. These effects require careful assessment.

Current projects at the University of Ulster:

|

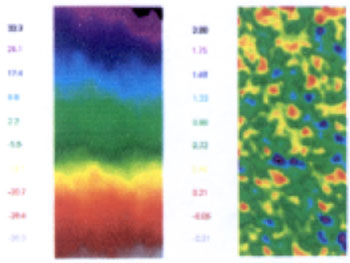

� compressibility of and resin flow within complex 3-D woven reinforcements

� dielectric cure monitoring of carbon fibre reinforced composites � consolidation and binding of complex woven preforms � modelling and analysis of composite materials with 3-D woven reinforcements. |

Areas of interest for new projects:

|

� in-tool, real-time cure monitoring and control during composite component manufacture

� influence of weave parameters on preform architecture and composite performance � processing-performance interactions for technical textiles. |

Specialist facilities in ECRE:

|

� power loom with electronic Jacquard control and 3-D weave design software

� autoclave and resin transfer moulding system � CAD and Finite Element Analysis (FEA) software � plastic injection moulding and extrusion facilities � materials testing laboratory including 3-D laser optical strain measuring system � comprehensively equipped thermal analysis laboratory. |

Contact: Prof. Robert McIlhagger, Engineering Composites Research Centre,

School of Electrical & Mechanical Engineering, University of Ulster, Newtownabbey, Co Antrim, BT37 OQB;

Tel: 028 9036 8120; Fax: 028 9036 6864;

E-mail: [email protected] ; Web: http://www.engj.ulst.ac.uk/ECRE/