| 2003 |

|

YEAR BOOK |

Trinity College Dublin

|

Research in Mechanical and Manufacturing Engineering at TCD

|

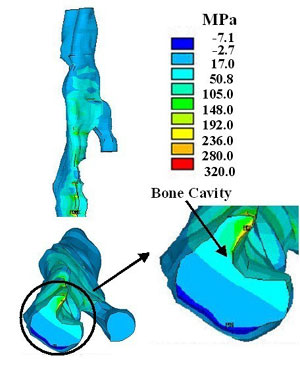

Activities of the Bioengineering group include: Tissue Engineering; Finite Element Modelling and PreClinical Testing of Orthopaedic and Cardiovascular Implants; Biomechanics of Injury; Biomechanical Response of Tissues and Bio-Fluids; Biomechanical Studies of Osteoporosis and its Treatment. In 2002 the group obtained �5.4 million to establish the Trinity Centre for Bioengineering, including purpose-built laboratories for tissue engineering, cell culture and biomechanical testing. Postgraduate activities also include an MSc taught-course in Bioengineering which equips students to work in the rapidly-expanding medical device industry.

The Fluids & Vibrations group works on a wide range of interdependent disciplines in which specific expertise has been developed and used to generate innovative solutions to complex problems in engineering applications. The work is based on applications in Fluid Mechanics, Aeroacoustics, Thermodynamics & Combustion, Heat Transfer and Acoustics & Vibrations. A number of current projects are focused on development of new technologies for aircraft noise reduction, including coordination of a �2.3 million project on the development of new technologies for the prediction of Jet Noise (JEAN - Jet Exhaust Aerodynamics and Noise).

The Manufacturing & Materials Group is concerned with modelling and measuring the properties of materials, especially regarding their performance in manufacturing operations, their friction and wear behaviour and their failure by fatigue and other fracture mechanisms. Current projects include: Finite Element Analysis of Machining and Forming Processes; Repair of Aircraft Turbine Blades; Analysis of Wear and Lubrication; Mechanics of Grinding; and Prediction of Failure in Engineering Components Using Critical Distance Mechanics. Currently the Materials Processing Research Centre is undertaking work to the value of �2.1 million to solve problems in the manufacture of components for a wide range of industries.

Contact: Head of Department, Prof. John Monaghan; E-mail: [email protected]