| 2002 |

|

YEAR BOOK |

ENTERPRISE IRELAND - THE NATIONAL METROLOGY LABORATORY

|

Physics in the last decimal place

|

NML maintains national reference standards and associated scales for most commonly encountered physical quantities- including length, mass, temperature, pressure, force, torque, frequency, and electrical quantities. These standards are disseminated by means of a calibration service delivered either directly to users or via commercial accredited calibration laboratories. By its very nature, metrology is an international activity. NML is an active member of the international metrology community, and Paul Hetherington, the Head of NML, currently holds the chair of EUROMET- the European collaborative organisation of European national metrology institutes ( http://www.euromet.org ). NML is a signatory to the Mutual Recognition Arrangement between national metrology institutes drawn up by the International Committee of Weights and Measures ( http://www.bipm.org ). As part of the on-going development of its measurement standards and facilities, NML carries out a programme of applied research in several areas of measurement technology.

Measuring precisely in 3-D

Co-ordinate measuring technology, using co-ordinate measuring machines (CMMs), has become an indispensable tool of industrial quality assurance. Co-ordinate measurement is basically point-by-point metrological recognition of a work piece by probing its configurative surfaces with a CMM. These CMMs are impressive machines, some with working volumes big enough to fit an entire truck, yet featuring measuring precision in the micrometer range. Jim O'Donnell is investigating the quality of the measurement results produced by CMMs. In particular, a user-friendly method of regularly verifying the performance of a CMM has been developed. This procedure is based, in part, on the experience gained during measurements carried out using NM's own CMM (Zeiss UMC850) on a large (1m x 0.5m x 0.5m) artefact during an international collaborative project. Of the 200 or so CMMs used in Ireland, many are making critical dimensional measurements upon which the quality of the end product depends. The advantage of this research project to the CMM user is the ability to quickly and easily verify the accuracy of the machine.

Is the Irish volt drifting?

An ideal measurement standard would have a value which is time invariant and completely immune to the effects of external influences. Except in the case of so-called 'intrinsic standards', whose values are based directly on the fundamental constants of nature, such ideal measurement standards do not exist. For a laboratory such as the NML which uses material standards, the task is to maintain an invariant representation of a physical unit in the presence of drift and outside influences. This is just what Oliver Power in the Electrical Section is doing in the case of the unit of electric potential, the volt. The work is being carried out in co-operation with Dr James Walsh of the School of Physics, DIT, Kevin Street ( http://www.physics.dit.ie/postgrads/opower/index.html ). At NML, the voltage unit is maintained by means of a group of electronic voltage standards which use Zener diode based reference elements. Innovative techniques are being used to investigate the effects of time, temperature, pressure and humidity on these standards.

Getting on the right wavelength

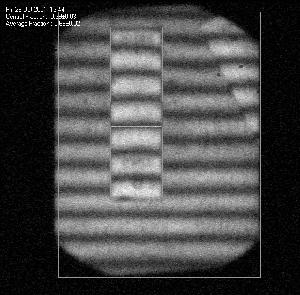

In the Dimensional Section, a project is underway which will allow the measurement of the length of steel gauge blocks in terms of the wavelength of light. Gauge blocks are widely used in industry as reference standards of length. Sean Peyton of NML and Micheal O'Hora, a research student from DIT, Kevin Street, are modifying and improving a gauge block interferometer which works on the Fizeau principle. A CCD (charge coupled device) camera and frame grabber are used to capture the fringe pattern (Figure 2) which is then analysed to extract the required information. The effect of the refractive index of air must also be taken into account, and work on the continuous monitoring of the air density is underway. The ultimate aim of the project is to improve by an order of magnitude the accuracy with which the axial length of gauge blocks can be measured at NML.

Contact: Oliver Power; Tel: + 353 1 808 2252;

E-mail: [email protected]