| 2002 |

|

YEAR BOOK |

Enterprise Ireland � Technology Development Division

|

Developing and delivering leading edge

technologies for industry

|

The Applied Research & Development Department has extensive expertise and facilities in the following areas:

��Ceramics

��Corrosion

��Organic coatings

��Powder technology

��Surface engineering

��Metal finishing.

Below are examples of projects in which the Technology Development Division is currently involved.

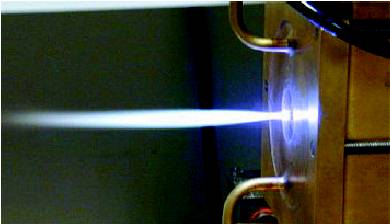

Novel atmospheric plasma for surface activation/treatment of polymers

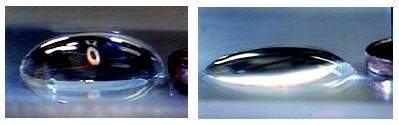

Many of the polymers used in medical device or in packaging applications, such as Teflon and polypropylene, have low surface energy. This causes difficulties for adhesively joining polymers together and for the adhesion of printing inks. Plasma treatment of the polymer surface can solve these problems. When placed in contact with an excited gas, bonds at the surface of the polymer are broken, which facilitates the adhesive bonding and/or printing operations. Only the top few molecular layers of the polymer are modified, without changing the polymer bulk properties. The wettability of the polymer surface can be dramatically altered, with plasma treatments generally leading to enhanced wettability or a hydrophilic (water loving) surface.

There are two types of plasma treatment that are commonly used, namely activation, and grafting. In surface activation, different reactive gases in the plasma � such as oxygen or nitrogen � are used to create different functional groups, which modify the hydrophilicity of the polymer surface. In plasma grafting, inert gases such as argon can be used to remove atomic species from the polymer, generating reactive and cross-linked surfaces.

The surface of polymers can also be altered through the deposition of coatings using plasmas. We have recently begun experiments on the treatment of polymers in low-pressure radio frequency (rf) plasmas containing fluorinated gases. The resulting nanometer thick fluoride based coatings are hydrophobic (water hating) and also exhibit reduced surface roughness. The high level of water repellency of these coatings means they could have considerable potential for the medical device and textile industries. We plan to extend these studies to atmospheric plasma treatments of polymer in the near future.

| Contact: Dr Denis Dowling, Surface Engineering Group; Tel: 01 8082403; Fax: 01 8082046; E-mail: [email protected] |

Impending legislation to control solvent emission from decorative paints

The Coatings Research Centre at Enterprise Ireland has concluded a study for the EU commission (DG Environment) to investigate the potential for a product-based approach to reduce emissions of volatile organic compounds (VOCs or solvents), due to the professional and non-professional use of decorative paints and varnishes. The product-based approach means defining the maximum concentration of solvent allowable in each specific category of product, available-off-the shelf. The EU Commission have already taken steps to limit VOC emission from industrial processes by means of the Solvent Emissions Directive 1999/EC/13, which places an installation emission limit on specified activities.

Extensive data were collected on market demographics, technical capability of reduced VOC products compared with conventional products, and the economic implications associated with regulation. Information was obtained through meetings with manufacturers, raw material suppliers, industry associations and questionnaire surveys. Extensive laboratory evaluation at the Coatings Research Centre was conducted to benchmark the VOC content of current products.

Paint manufacturers

Despite the recent trend of concentration, there are almost 1,300 significant paint manufacturers, and over 3,200 when very small localised family businesses are included, in the European Union and six major 'accession countries'. These employ about 122,000 workers. However, the ten largest paint manufacturers account for almost 50% of total production. The southern European markets tend to be less concentrated than the northern European markets. The total annual production of decorative coatings in the EU member states was about 3344 kilotonnes in 1997. The total production value was at least �5.2 billion, while the retail value was considerably higher. When the six accession countries are included, the production is about 3800 kilotonnes.

Paint retailing

More than 150,000 retail outlets for decorative coatings exist in the EU. Professional painters may purchase directly from the manufacturer, at wholesalers, or in producer-owned specialised retail stores. In the Do-It-Yourself (DIY) sector, the market share of DIY superstores is rising. The number of known DIY superstores in major chains is about 8,000. Currently, the top 15 DIY chains own over 40% of all stores.

Painting Contractors

At the other end of the market, over 165,000 professional painting companies exist in the EU, which employ about 1.65 million painters. The split between professional and DIY-paint consumption ranges from about 30% DIY in Greece to around 70% DIY in Sweden and Finland. Labour costs of professional painters and the increasing DIY-trend are major determining factors in this. The increased DIY-trend, as well as the increasing availability of cheap, non-qualified painters, is seen as a threat to their business, as are restrictions on the use of high VOC products by professionals. Among DIY-retailers 'Own label' brands are used for price competition, while prices of well-known brands are maintained.

The overall market share of waterbased paints across the EU is about 70%. Highest penetrations can be found in the Scandinavian countries, Germany, Austria, Portugal and Spain; lowest penetrations in France, Italy and Hungary. Waterbased coatings dominate for wall paints, while joinery paints and varnishes are predominantly solventborne. In most countries, the market share of waterbased paints is lower among professional painters than in the DIY-sector. However, in some countries, occupational health regulations have resulted in the opposite trend.

VOC or solvent emissions

The VOC-emissions due to the use of decorative paints and varnishes in the EU-member states and six major accession countries have been estimated at 720�830 kilotonnes annually. The contribution of the decorative paints sector to total man-made VOC-emissions in the EU is currently about 4�5%. The relative contribution of the decorative paints sector may rise to about 10% after implementation of the Solvents Emissions Directive (SED), which aims at a 50% VOC-reduction.

Main VOC-reduction proposals.

The reduction scheme represents a reduction potential of 493 kT or 51�60% of VOC emission associated with the use of decorative paints and varnishes. This study has now formed the basis of a proposed directive from DG Environment.

| Contact: Dr John Colreavy, Coatings Research Centre; Tel: 01 8082484; Fax: 01 8374499; E-mail: [email protected] |

The Institute of corrosion � Dublin Branch

Corrosion Technology in Ireland: Past, Present and Future was the title of a Seminar held on 21 February 2002 at Enterprise Ireland's premises in Glasnevin. This event marked the launch of the Dublin Branch of the Institute of Corrosion (I Corr, formerly the Institute of Corrosion Science and Technology). The seminar was well-supported, with people in attendance from a wide range of industrial and government organisations. Speakers dealt with a range of topics � including the history of corrosion technology, corrosion problems associated with reinforcing bars in concrete, renovation of Dublin's historic Ha'penny Bridge (see Figure 4), and a survey of the atmospheric corrosion of zinc throughout the island of Ireland. Since then technical meetings have been held on a number of topics.

I Corr is a learned society that has been serving the corrosion science, technology and engineering management needs of individuals, academics and industry for over forty years. With approximately 4% of a country's GNP being attributed to the cost of corrosion each year, it has long been the aim of the organisation to raise awareness of the issues involved with protecting valuable assets from the ravages of corrosion. Key to this fight are the establishment and promotion of sound corrosion management practices, through cost effective corrosion control measures and a sustained effort generally to raise awareness at all stages of design, fabrication and operation. By studying the mechanisms of corrosion, we gain an understanding of its causes, and this assists in forming strategies to overcome or at least minimise its future impact.

Exchange of information concerning corrosion issues is a crucial role of the organisation. By holding technical meetings at regular (bimonthly) intervals, seminars, training programmes, and with an annual conference, it disseminates information to both I Corr members and to those who attend from outside organisations. Continuing Professional Development (CPD) is now a requirement of many other professional organisations and this provides an ideal opportunity for contact and educational enhancement. In addition to local branches (including one in Cork and another in Dublin), the Institute also has a Corrosion Science Division.

The 2002 conference is to be held in Cardiff, Wales from 22 to 24 October. In addition to technical papers on topics such as protective coatings, cathodic protection and monitoring, the conference will also feature a mock tribunal on a marine coatings failure. A Seminar based on coating technology topics is also scheduled to be held in Dublin on 21 November 2002.

Further information is available at the I Corr web site www.icorr.demon.co.uk

or E-mail [email protected] .

Alternatively the Chairman of the Dublin Branch can be contacted: Dr Tony Betts;

Tel: 01 8082541; Fax: 01 8082046; E-mail: [email protected]